Welcome to MATSE 436. This course presents an in-depth view of the

mechanical properties of materials, developing critical

skills that can be applied to contemporary issues in research,

development and production. The syllabus for the course is

outlined in the following sections.

OUTLINE

Reference

Books: Back to

outline

Introduction to the Mechanical Properties of Ceramics, D. J. Green. There are some errors in the book. To obtain corrections click here

Materials Selection in Mechanical Design, by M.F. Ashby

Goals and Course Objectives:

The objectives of the course

are to give the student a fundamental understanding

and appreciation for the relationship between the structure

and mechanical behavior of materials.

Course Description:

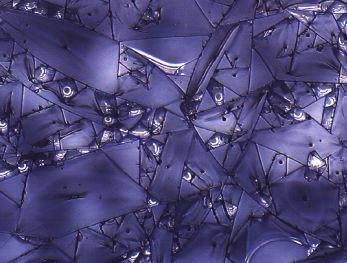

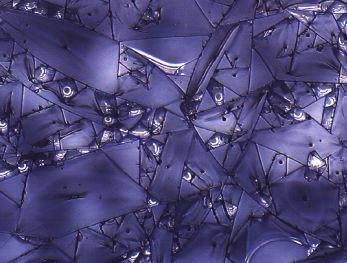

The course teaches the students the fundamental relationships between the

structure and mechanical behavior of materials. The critical concept

is that the mechanical properties of materials can be controlled by careful

design of the structure of the material and this idea is the basic foundation

of the course. The structural effects that can influence mechanical

behavior can range in scale from the sub-atomic level, through the nano-

and microstructural levels to the macroscopic. For example, the students

learn that properties can be controlled by changing grain size and shape,

the addition of other phases to produce composites, etc. The course incorporates

the most recent ideas in materials engineering as examples of this design

philosophy. In order to accomplish the above goals, a comprehensive

understanding of the mechanics concepts needed for the processing, utilization

and design of engineering materials must be developed. The students must

understand the design process for selecting materials for engineering applications.

Within this design process, the key mechanical properties of materials and

the techniques for their measurement must be appreciated. Once the critical

properties are identified, the combination of parameters that describe the

performance within engineering applications must be understood.

Materials can exhibit a wide range of deformation types: elastic, plastic,

viscous, etc., thus, the mechanics associated with all these processes must

be grasped. Materials can exhibit unexpected failure or loss of tolerance,

so it is particularly critical to understand the techniques that are used

to improve and assess mechanical reliability. Students will also be expected

to understand the techniques that are used for strengthening materials.

The overall goal is to provide the students with the skills that are needed

by material engineers to design and utilize materials with high mechanical

reliability.

* Prerequisites:

a) Courses Math

231, Math 250 or Math 251, Phys 214, MatSE 201 or 259 or E

Sc 314

b) Topic

Calculus of Several Variables, Differential Equations, Mechanics,

Introduction to Materials Science

* Course Topics:

Course Outcomes:

Graduates will understand:

Graduates will be able to:

Students must contact the instructor prior to the due date of the homework

if they are unable to complete the work. If a

student is unable to participate in an exam, they must contact

the instructor prior to these events. The student should

also make an appointment with the instructor to determine a

date by which these tasks will be completed. See Senate

rules 44-25 and 44-35. At least 7 days notice will be given for

the dates of the in-class exams and for the due dates of the homework

and term paper.

Back to outline

Department

Objectives and Outcomes:

The Department of Materials Science and Engineering has a set of educational objectives and outcomes (http://www.matse.psu.edu/academics/ug-objectives.html). The following tables show how the objectives and outcomes of MatSE 436 relate to those of the Department.

Relation of Course Objectives to Department Objectives

| Course Objectives |

Relates to Department Objectives |

| 1. Understand the continuum definition of strains

and stresses. |

1, 6 |

| 2. Understand the application of the generalized

version of Hooke’s Law |

1, 6 |

| 3. Understand the relationships between structure

and elastic properties of materials. Understand thermal stresses and

the definition of design stress. |

1, 2, 3, 6 |

| 4. Understand Newton’s Law for linear viscous materials

and the relationship between structure and viscoelastic properties of materials. |

1, 2, 3, 6 |

| 5. Understand the relationship between structure

and the plastic/creep deformation of materials. |

1, 2, 3, 6 |

| 6. Understand the basics of linear elastic fracture

mechanics and its application. |

1, 2, 6 |

| 7. Understand the use of fractography and the strengthening

processes used for ceramics, glasses, polymers and metals |

1, 2, 3, 6 |

| 8. Understand the process by which materials are

selected and contrast the differences between metals, polymers and composites. |

2, 3, 4 |

| 9. Work as a group to select a material for a chosen

application and present the conclusions as group reports. |

2, 4, 5 |

| 10. Work (in-class) as a group to answer comprehension

questions and problems. |

5 |

| 11. Research a topical area that involves mechanical

behavior and make a class presentation. |

5 |

Course Outcomes

Relationship of course outcomes map to the departmental outcomes:

| a | b | c | d | e | f | g | h | i | j | k | l |

| 1 | 2 | 2 | 3 | 1 | 3 | 2 | 3 | 3 | 2 | 1 | 1 |

1 = strongly related 2 = related 3 = unrelated

The course will be evaluated as follows;

1. Problem sets (7) - 35 %,

2. Group projects (2) - 15 %

3. Class exams (4) - 40%

4. Group presentation (1) - 10 %.

The grades for the above will be based on actual performance with slight

adjustments for difficulty. Audit students must obtain a passing grade

in the exams.

The following books have been placed on reserve and they are useful as

supplements to the course. Some books cover advanced

topics, others deal with the same subject matter but

from an alternative viewpoint.

| D. J. Green |

An Introduction to the Mechanical Properties of

Ceramics |

| R. W. Davidge |

Mechanical Behavior of Ceramics |

| A. H. Cottrell |

Mechanical Properties of Matter |

| B. R. Lawn |

Fracture of Brittle Solids: 2nd Edition |

| M. F. Ashby |

Materials Selection in Mechanical Design |

| J. B. Wachtman, Jr. |

Mechanical Properties of Ceramics |

| R. W. Hertzberg |

Deformation and Fracture Mechanisms of Engineeering

Materials |

| J. F. Nye |

Physical Properties of Crystals |

| T. H. Courtney |

Mechanical Behavior of Materials |

| W. Soboyejo |

Mechanical Properties of Engineered Materials |

Detailed Course Content

1. Introduction

1.1. The design process

1.2. Engineering materials: properties, processing and structure.

1.3. Material selection maps

2. Overview of mechanics

2.1. Uniaxial deformation

2.2. Other deformation modes

2.3. Strain definition

2.4. Stress definition

2.5. Deformation types

3. Elastic behavior

3.1. Engineering elastic constants

3.2. General version of Hooke's Law

3.3. Elastic behavior of isotropic materials

3.4. Relationship of elastic constants to atomic structure.

3.5. Rubber elasticity

3.6. Elastic behavior of particulate composites

3.7. Constitutive relations for random polycrystals and glasses

3.8. Effects of porosity and microcracking on elastic constants

3.9. Hierarchical effects of structure

3.10. Thermal expansion

3.11. Measurement of elastic constants

3.12. Elastic stress distributions

3.13. Thermal stresses and thermal shock

3.14. Definition of design stress

4. Viscosity and viscoelasticity

4.1. Newton's Law of viscosity

4.2. Temperature dependence of viscosity

4.3. Simple problems of viscous flow

4.4. Non-linear viscous flow

4.5. Viscoelastic models

4.6. Viscous deformation of non-crystalline materials

4.7. Viscous deformation of crystalline solids

5. Plastic deformation

5.1. Theoretical shear strength

5.2. Dislocations

5.3. Stress fields of dislocations

5.4. The geometry of slip

5.5. Yield strength of crystalline materials

5.6. Obstacles to dislocation motion: strain hardening, strain-rate hardening.

5.7. Plasticity in glassy and crystalline polymers.

5.8. Plasticity mechanics

5.9. Hardness

6. Creep deformation

6.1. Creep mechanisms in crystalline materials

6.2. Creep mechanisms in polymers and glasses

6.3. Deformation mechanism maps

6.4. Measurement of creep mechanisms

7. Fracture

7.1. Theoretical cleavage strength

7.2. Stress concentrations at cracks

7.3. Fracture strength and ductility

7.4. The Griffith concept

7.5. Linear elastic fracture mechanics

7.6. Stress intensity factor solutions

7.7. Fracture toughness measurements and R Curves

7.8. Environmentally-induced fracture

7.9. Fatigue

7.10. Contact and impact damage processes, impact testing

7.11. Fractography

8. Strengthening Processes

8.1. Toughening methods for brittle materials

8.2. Hardening methods for low temperature strength: polycrystalline deformation,

solid solution strengthening, intermetallic compounds, precipitation hardening,

and dispersion hardening.

8.3. Composite strengthening-polymer and metal matrix composites.

8.4. Strengthening of polymers: rubber and rigid particle composites.

Academic

Integrity and the Promotion of a Vibrant Learning Culture:

The following recommendations address the partnership between the faculty-teacher and student-learner in the personal process of learning with a focus on the maturation of students in the learning process (Senate Policy 49-20).

The Teacher in the Learning Process.

Maintaining a high level of learning

requires characteristics in teaching necessary for a

strong teacher-learner relationship. The teacher should:

a) Maintain an atmosphere of integrity, civility and respect.

b) Exhibit a strong desire for

students to learn.

c) Recognize that effective teaching

requires a balance among teaching, advising, research,

and service.

d) Encourage active student participation

in learning.

e) Employ effective teaching

and learning strategies.

f) Help students connect learning

experiences.

g) Develop an effective personal

teaching approach.

The Student in the Learning Process.

Maintaining a high level of learning

and scholarly activity requires the following characteristics

of the student learner:

a) Academic integrity, respect, and civility.

b) Strong work ethic.

c) Manage time wisely.

d) Participate actively in class.

e) Recognize importance of out-of-class

learning.

f) Reflect on the educational

process.

g) Perform self-assessment.

Academic Integrity (Senate Policy 49-20)

Definition and expectations: Academic integrity is the pursuit of scholarly activity in an open, honest and responsible manner. Academic integrity is a basic guiding principle for all academic activity at The Pennsylvania State University, and all members of the University community are expected to act in accordance with this principle. Consistent with this expectation, the University's Code of Conduct states that all students should act with personal integrity, respect other students' dignity, rights and property, and help create and maintain an environment in which all can succeed through the fruits of their efforts.

Academic integrity includes a commitment not to engage in or tolerate acts of falsification, misrepresentation or deception. Such acts of dishonesty violate the fundamental ethical principles of the University community and compromise the worth of work completed by others.

For MatSE 436 the following specific points should also be considered.

University policies for

undergraduate education

Back to outline

Will be posted on ANGEL

Class

Schedule:

3 credit class, taught in three 50 minutes classes per week.

Back to David J. Green Web Page

Prepared by: David J. Green, January 8, 2004.